工艺方案 Process scheme

————————————————

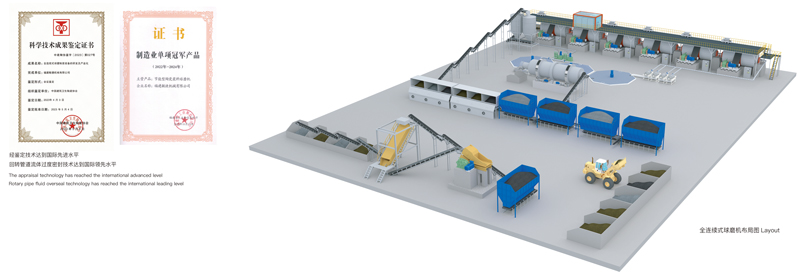

滚球官网体育(中国)有限公司工艺方案:将脊性料与塑性料分别预加工后进入连续式球磨机

(一),脊性料进球描述:

1.原料破碎至 3mm 后由装载车输送至标准料仓。

2.标准料仓底部配置皮带秤,将配置好的物料经输送带送至中转仓。

3.中转仓根据球磨产量向连续球磨机供料。

Full continuous ball mill process scheme: the ridge material and plastic material are respectively pre-processed into the continuous ball mill

(A), ridge material goal description:

1. After the raw material is broken to 3mm, it is transported to the standard silo by the loading truck.

2. The bottom of the standard bin is equipped with a belt scale to send the configured materials to the transfer bin through the conveyor belt.

3. The transfer warehouse supplies materials to the continuous ball mill according to the ball mill output.

(二).化浆描述:

1,根据配方由喂料机向化浆连续球磨机输送塑性料,同时按工艺设计添加适量的水分与塑性料一同化浆,

2.化浆连续球出浆,浆料经振动圆筛过筛后先行除铁再输送至地下浆池均化待用

3.化浆球出浆端设计有过滤锥桶,将原料中所含的杂质筛除

4.振动圆筛筛除浆料中所含的沙石颗粒并输送至沙石仓统-外理

5,地下浆池的浆料根据工艺设计按配方、按产量经由柱塞泵向连续球磨机供浆

1, according to the formula from the feeder to the slurry continuous ball mill to transport plastic material, at the same time according to the process design to add the appropriate amount of water and plastic material assimilation slurry,

2. The slurry is continuously pelted out. After the slurry is sifted through the vibrating round screen, the iron is removed and then transported to the underground slurry pond for homogenization and waiting for use

3. A filter cone bucket is designed at the pulp end of the slurry ball to screen out the impurities contained in the raw materials

4. Vibrating round sieve sieve the sand particles contained in the slurry and transport them to the sand silo system - external processing

5, the slurry of the underground slurry tank is supplied to the continuous ball mill through the plunger pump according to the process design, according to the formula and the output

产品优点 Product advantage

————————————————

连续式球磨机与间歇式球磨机相比有如下优点

1.连续式球磨机最大的优点是节能、环保( 详见能耗对比说明表 );

2.连续式球磨机通过不同球的研磨分工,逐渐研磨,粒度分布均匀,避免过磨;

3.在同样产量规模下,连续式球磨机占地面积更少,大幅度减少投资;

4.可减少人工,并降低工人的劳动强度,节约卸料的时间;

5,由于连续式球磨机筒体内温度的升高和动态出浆,使得出磨泥浆的粘度降低,从而减少了球磨物料的用水量和喷雾干燥塔的蒸发量,节能效果明显。

The continuous ball mill has the following advantages over the intermittent ball mill

1. The biggest advantage of continuous ball mill is energy saving and environmental protection (see energy consumption comparison table for details);

2. Continuous ball mill through different ball grinding division, gradually grinding, uniform particle size distribution, avoid grinding;

3. Under the same production scale, continuous ball mill covers less area and greatly reduces investment;

4. Can reduce labor, and reduce the labor intensity of workers, save the time of unloading;

5, due to the rise in the temperature of the continuous ball mill cylinder and the dynamic pulping, the viscosity of the grinding mud is reduced, which reduces the water consumption of the ball mill material and the evaporation of the spray drying tower, and the energy saving effect is obvious.

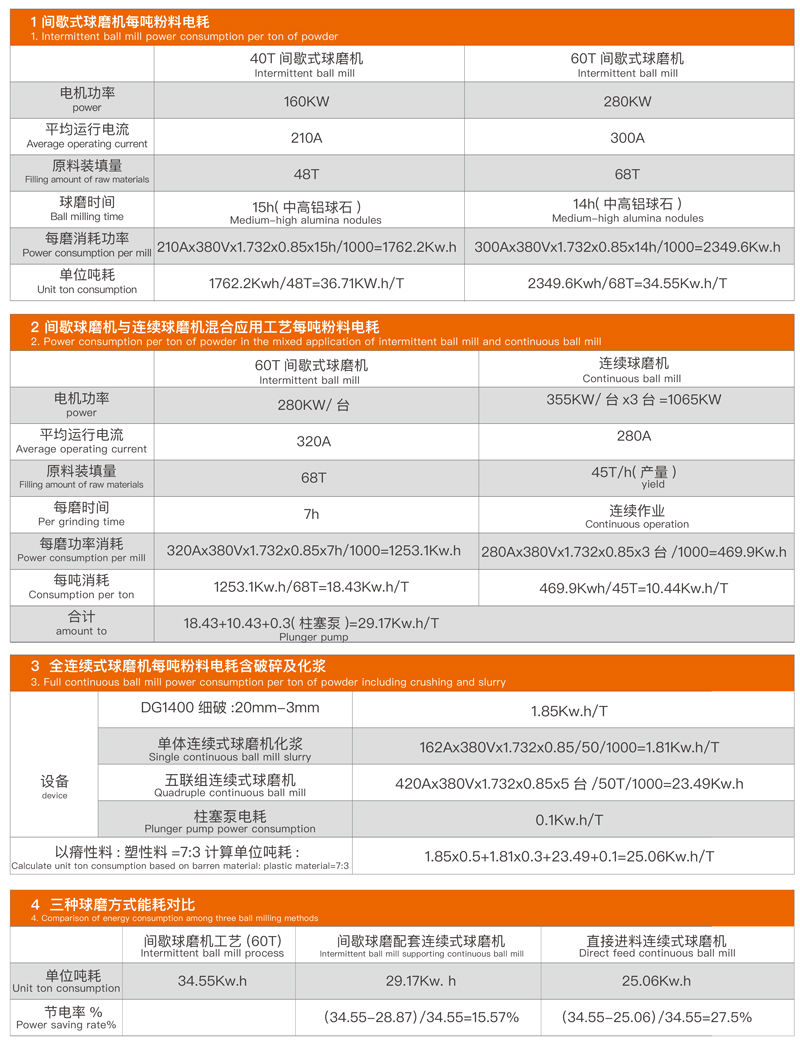

设备能耗对比说明 Comparison of equipment energy consumption

————————————————

原料颗粒 10-20mm,成品浆料细度 250 目筛余 0.8-1.0

Raw material particles 10-20mm, fnished stock fneness 250 mesh screen size 0.8-1.0